Ensure Quality and Compliance with Our WMS for Cold Storage

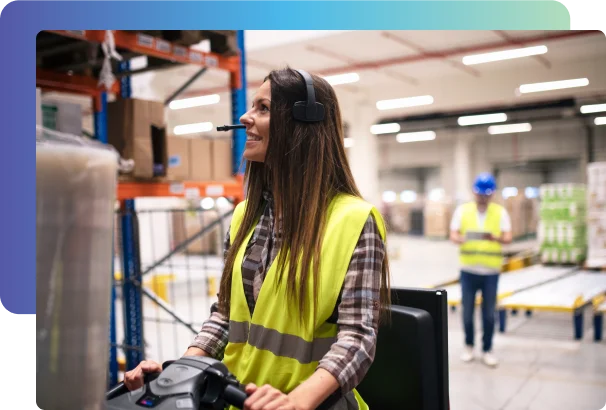

The cold chain industry relies heavily on cold storage providers and cold storage warehouse companies as they are the backbone of global logistics. They manage various temperature-sensitive products, encompassing perishable food, pharmaceuticals, and chemicals. They also control environmental conditions precisely to avoid spoilage and ensure compliance with the regulatory standards. Businesses are empowered by advanced cold storage warehouse management systems (WMS) through real-time temperature monitoring, inventory control, and data-driven decision-making. These systems reduce operational costs, minimize waste, and maximize product shelf life through streamlined processes.